Explosion Proof CHEMSTAR

Innomotics XP CHEMSTAR meets the IOGP specification - THE new standard for oil & gas

The International Association of Oil & Gas Producers (IOGP) is a worldwide forum for members of the oil industry, founded in London in 1974. The participants regularly debate on issues related to health and safety, environment, social responsibility, engineering, and operations.

The aim is to achieve improvements in these areas, based on collecting operational data which is published each year.

XP CHEMSTAR from A to Z

Every year, millions of low voltage motors based on the Innomotics platform roll off the production line. What distinguishes them are high quality standards, short delivery times, and simple but fast workflows from planning to procurement, engineering and integration, all the way to operation.

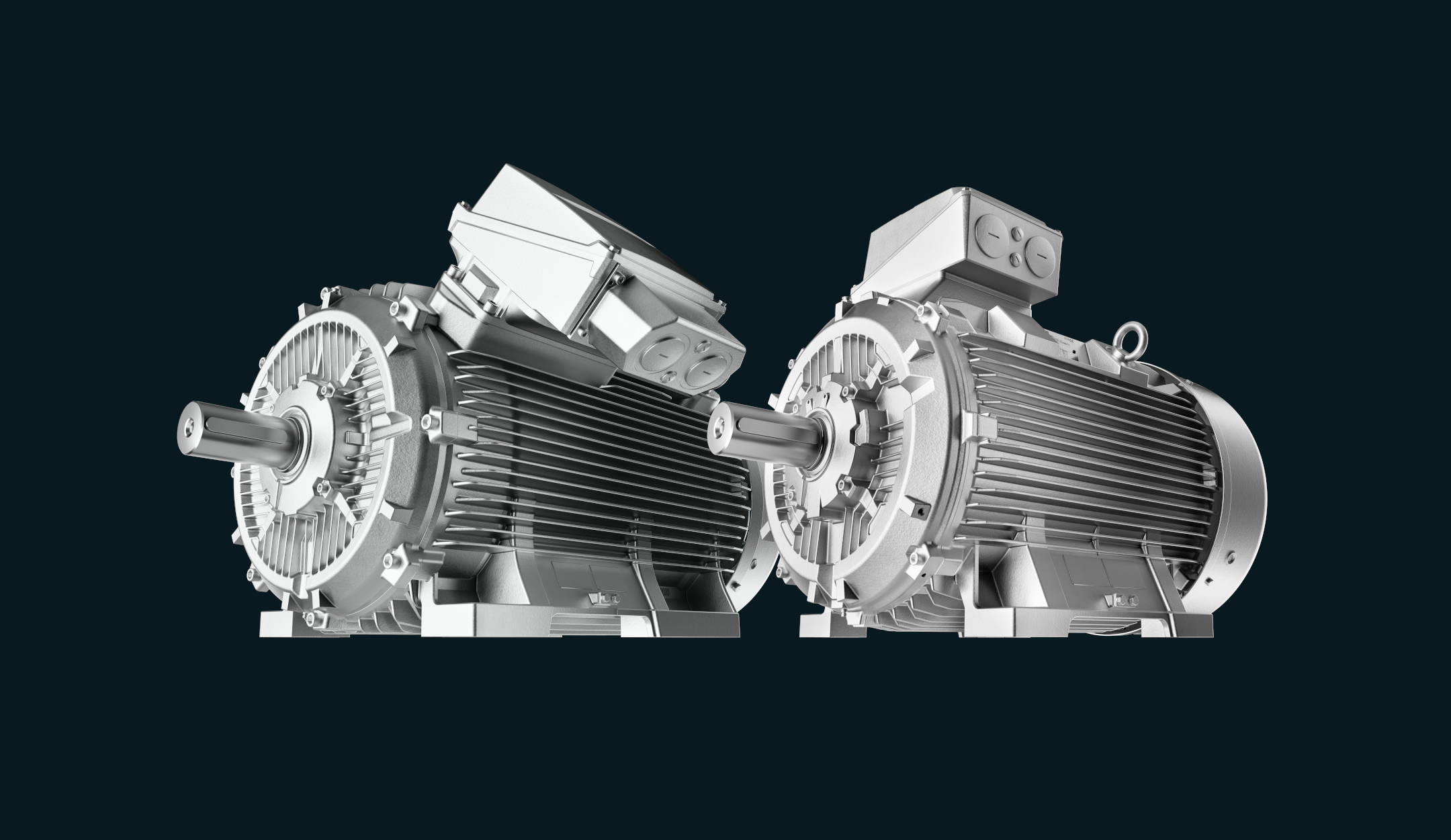

CHEMSTAR technology also available for Severe Duty Motors

To meet the most demanding applications in the oil & gas and chemical industries, our reliable and powerful Innomotics SD Severe Duty Motors are also available with CHEMSTAR technology.

Whether oil, gas or chemicals - The motor made for harsh environments

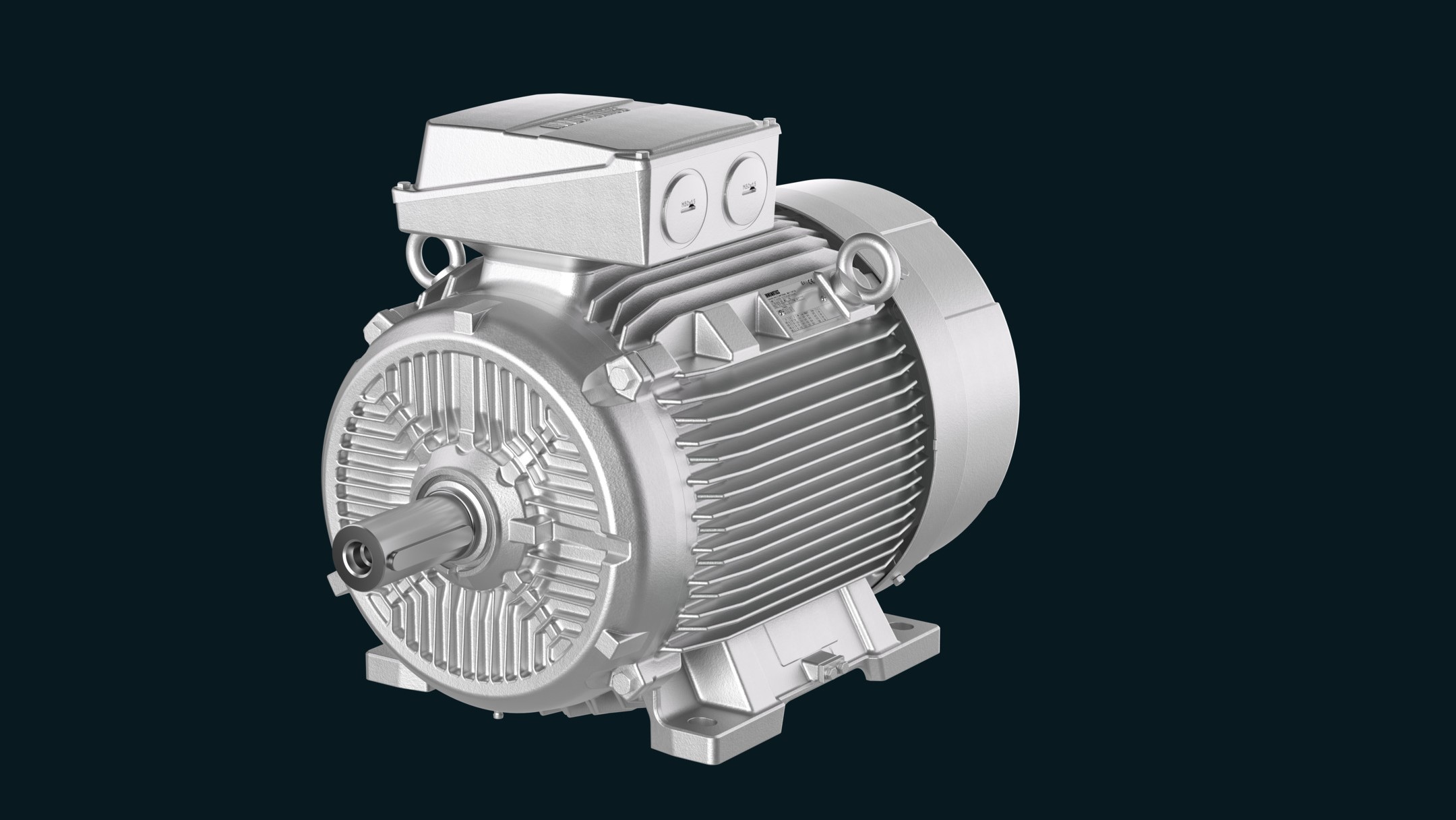

Our new generation of motors covers the range from 0.25 to 500 kilowatts (kW) for protection types of Zones 1 and 2 in Ex eb, Ex ec, Ex db, Ex tb and Ex tc. The motors have a very robust design with an enclosure and end shields made of gray cast iron and a steel fan cover.

The high efficiency (efficiency class IE3) minimizes your operating costs. Pre-defined, practical configuration packages – with special corrosion protection coatings of category C4, stainless steel screws and bolts, or extended warranty – allow the motors to be deployed in the chemical, oil & gas industries. In addition, there are freely selectable options, such as reduced starting currents, motor monitoring, reinforced bearings, or tropical climate design.

Large-scale plants in particular, high investment costs and long lifecycles, as well as the increasingly stringent requirements for environmental and emissions protection in the petrochemical and oil & gas industries call for maximum performance and the greatest possible efficiency.

Increasing scarcity of resources, rising cost pressure, extensive safety requirements, and strict environmental stipulations do not allow any compromises when choosing drive technology.