Innomotics HV M

High voltage motors with a modular cooling concept.

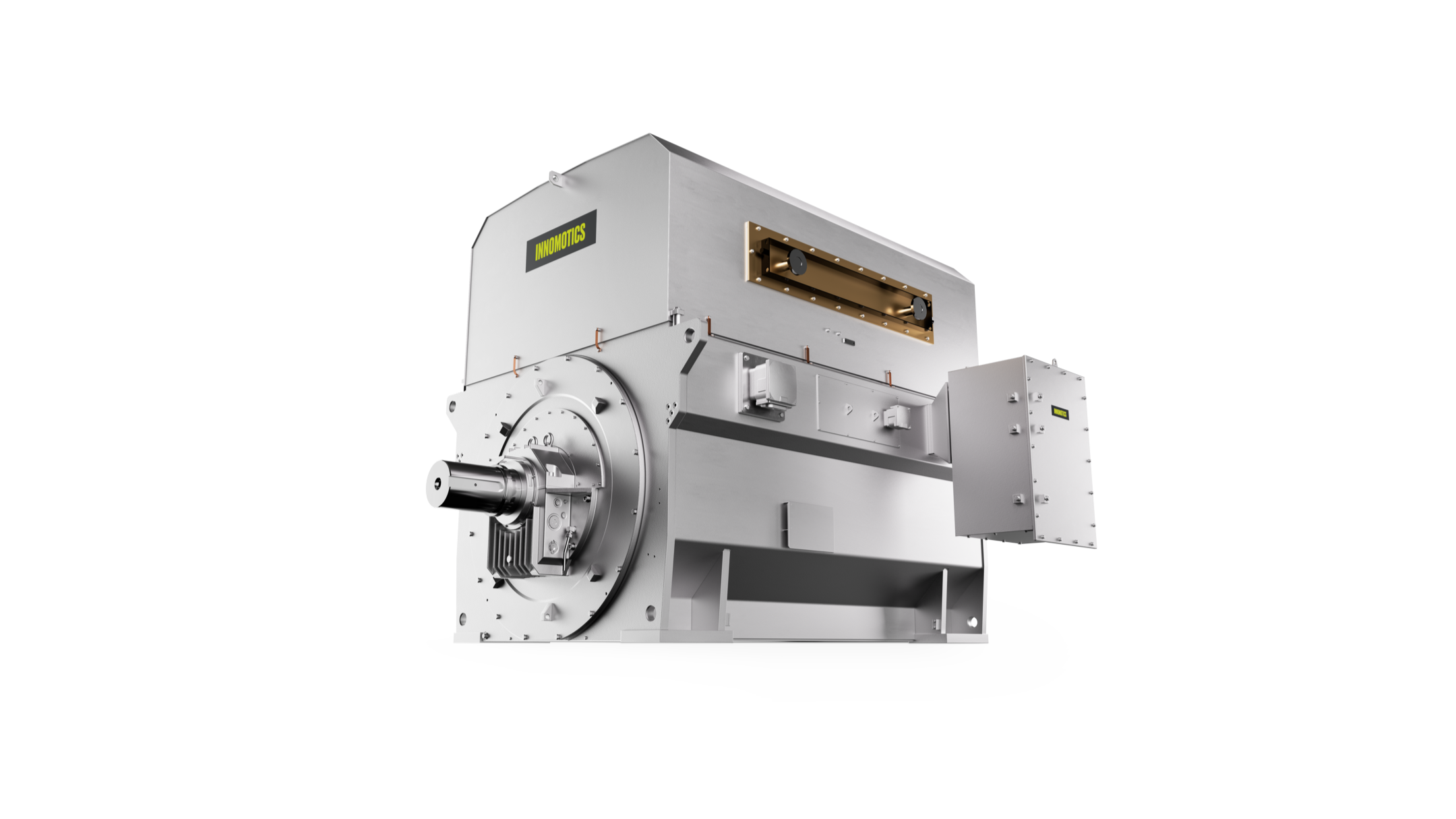

High voltage motors Innomotics HV M

High voltage motors with a modular cooling concept can be used in many industries such as oil & gas, water & wastewater, power generation etc. The motor provides reliability, mechanical stiffness and reduced noise values, as well as being weight-optimized for exact application needs.

Benefits at a glance

Innomotics HV M – Picture gallery

Technical data overview

Shaft height | 450 up to 560 mm: cast iron enclosure (welded steel on request) 630 up to 900 mm: welded steel enclosure |

|---|---|

| Power rating | up to 29 MW |

| No. of poles | 2 - 12 poles (other pole numbers on request) |

| Rated voltages | 3 - 13.8 KV (also available as low voltage version) |

| Degree of protection | IP23, IP24W, IP55, IP56 non-heavy-sea |

| Cooling type | IC 01 IC 81 W, IC 86 W IC 611, IC 616, IC 666 |

| Efficiency | up to 98 % |

| Explosion protection | Increased safety, Zone 2, Ex ec Pressurized, Zone 1, Ex pxb, Ex pzc, Ex tc |

Downloads, Support & Services

- Downloads

- Support

- Services

Technical documentation

References and applications

M. KAINDL OG, WALS, AUSTRIA

Drive-train replacement of a dryer fan

- The M. Kaindl OG in Austria is among the world leaders in laminate flooring and Europe’s market leader in manufacturing boards for furniture and interior applications. Kaindl uses more than 1,000 atro tons (ATR) of wood within 24 hours predominantly from sustainable forestry. To process the raw material in the board, it needs to be shredded, cleaned and dried.

HANSON CEMENT, ESSEX, UNITED KINGDOM

Inspire IQ for Hanson Cement's Ketton and Purfleet plant

- The Innomotics HV M motors which driving the back-filter fans, are controlled by the SINAMICS* PERFECT HAMRONY GH180 drives. Each day over 1000 data points are captured to the cloud. Through the implementation of Inspire IQ together with Innomotics (former Siemens* Large Drives), Hanson Cement can use the collected data to monitor the drive-train 24/7 and to plan their maintenance intelligently. Due to this data-analytics system, Innomotics is able to offer services such as Expert Assistance and Expert Diagnostics.