Innovative Maintenance for a Sustainable Tomorrow

Integral Plant Maintenance (IPM)

Since its founding in 1847, Innomotics (former Siemens* Large Drives) has been synonymous with outstanding engineering and innovative technologies. Over the decades, we’ve built an impressive history in the services sector that endures to this day.

IPM, established in 1999, has evolved into a globally recognized provider of top-notch maintenance services.

Our mission is clear:

We deliver “Safe”, “Reliable”, “Innovative”, and “Sustainable” Maintenance for Industrial Plants.

Those core values are shaping our daily operations.

Welcome to Innomotics IPM – your partner for sustainable and future-proof maintenance

Customer Value: We take pride in being highly valued by our global customers. Our strong safety and value culture and commitment to continuous employee training contribute to our success.

Cutting-Edge Technology: Our professionalism and constant advancements in maintenance practices, driven by cutting-edge digital technologies, receive consistently positive feedback.

Leadership: Our position as a world leader among IPM providers is a result of our long history, tradition, and ability to stay ahead of the curve. We develop innovative solutions that exceed customer expectations.

Join us on this journey toward a more resilient, sustainable, and efficient industrial landscape.

At the heart of our Integral Plant Maintenance strategy lies a commitment to seamless, technologically advanced practices that harmonize all facets of maintenance with overall plant operations. Our vision encompasses the following key principles

Predictive and Preventive Approaches: We prioritize proactive measures over reactive fixes. By leveraging data analytics, real-time monitoring, and predictive maintenance techniques, we aim to anticipate issues before they impact production.

Sustainability: Environmental stewardship is integral to our approach. We strive to minimize waste, optimize resource utilization, and reduce our ecological footprint. A well-maintained plant contributes to a healthier planet.

Employee Empowerment: Our workforce is our greatest asset. We empower employees with the knowledge, tools, and autonomy needed to maintain equipment effectively, ensuring that our highly trained staff deliver the safest and highest quality maintenance.

Enhanced Reliability and Efficiency: By integrating maintenance seamlessly into plant operations, we enhance reliability, minimize downtime, and maximize overall efficiency.

At Innomotics Integral Plant Maintenance, our mission is to provide you with top-notch maintenance solutions grounded in the core values of safety, reliability, innovation, and sustainability.

Safety: Safety is our top priority. We employ the latest technologies and best practices to ensure that your facilities operate safely and efficiently. Our goal is to create a risk-free working environment for your employees, placing the highest emphasis on occupational safety to protect everyone on-site.

Reliability: We understand the importance of keeping your operations running smoothly. With our extensive experience and deep expertise, we offer customized solutions that maximize your uptime and minimize unexpected downtimes.

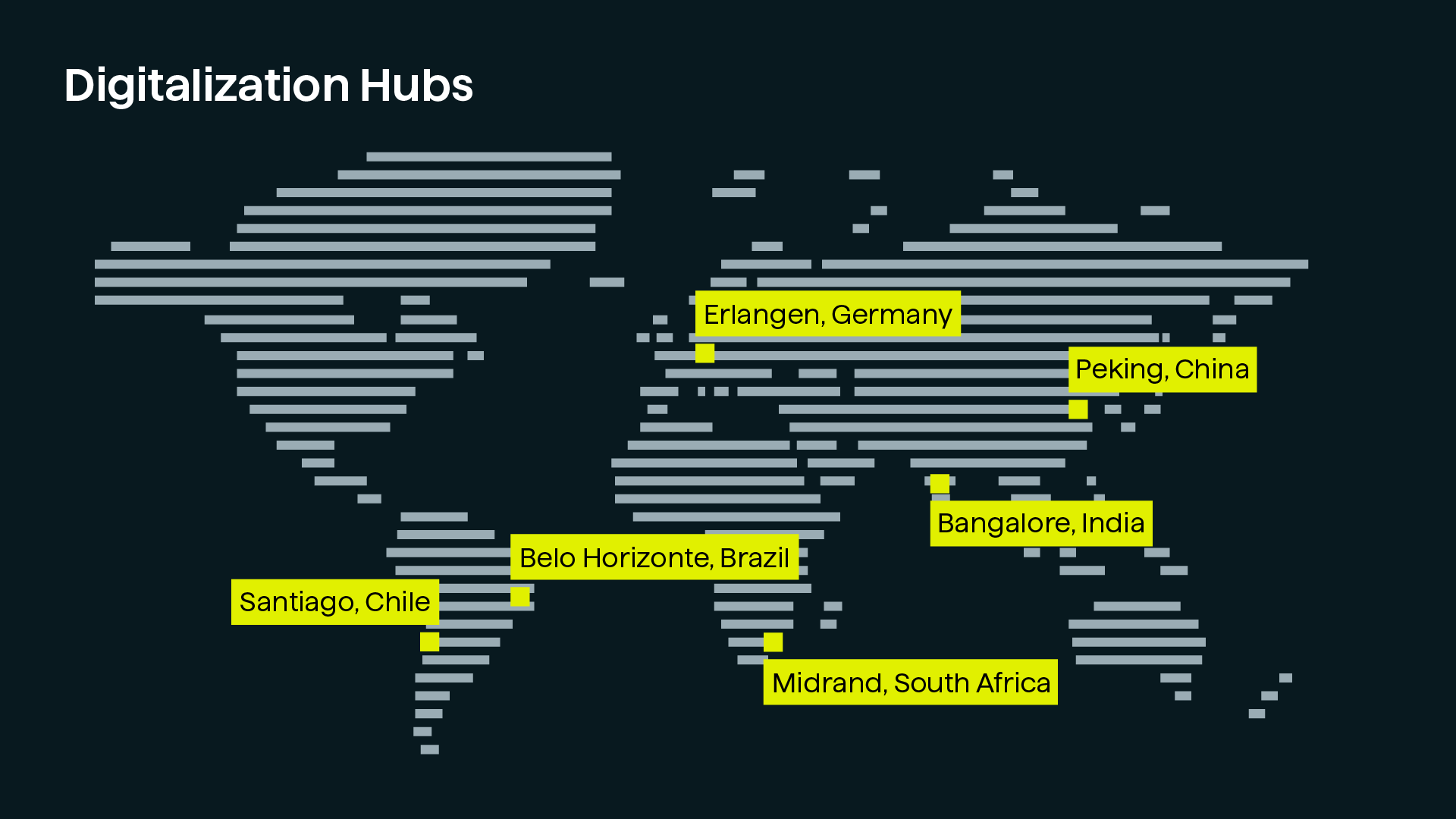

Innovation: In a rapidly changing world, innovation is key to success. We continuously invest in research and development to bring you the latest technologies and innovative maintenance solutions. Our six global digital hubs are dedicated to developing digital solutions that optimize your operations.

Sustainability: Sustainability is a fundamental part of our business strategy. We are committed to eco-friendly practices and solutions that enhance your operational efficiency while minimizing your environmental footprint. Together, we strive to create a more sustainable future.

Our commitment to these values ensures that you benefit from premium maintenance services while guaranteeing the safety, reliability, and sustainability of your facilities. We are proud to be your trusted partner and look forward to providing you with innovative solutions that exceed your requirements and expectations.

Integral Plant Maintenance Services

At Integral Plant Maintenance, our services go beyond the boundaries of a typical service contract. We offer comprehensive and efficient solutions for plant upkeep, ensuring optimal performance and reliability. Our IPM portfolio is built on a holistic and comprehensive approach that considers all relevant aspects from preventive maintenance to ad-hoc services, spare parts management, and operations management.

This includes the following elements:

Global Innovation Through Six Digital Hubs

We are driving innovation through six digital hubs dedicated to advancing IPM solutions.