Innomotics DP Definite Purpose Motors

Sector motors: The precise solution to address individual requirements

Innomotics DP Definite Purpose Motors

Going beyond the standard program, sector motors offer a precisely fitting solution to address individual requirements. Every sector has its own requirements when it comes to drive technology. As a full-line supplier and based on our many years of experience, we precisely understand these requirements.

The precisely fitting solution to address your specific requirements

We are always on the search for innovative solutions to achieve optimum cost-effectiveness. This is why, in addition to our standard program, we also offer Definite Purpose motors. These fully satisfy all sector requirements, therefore guaranteeing the highest degree of efficiency.

Full speed ahead

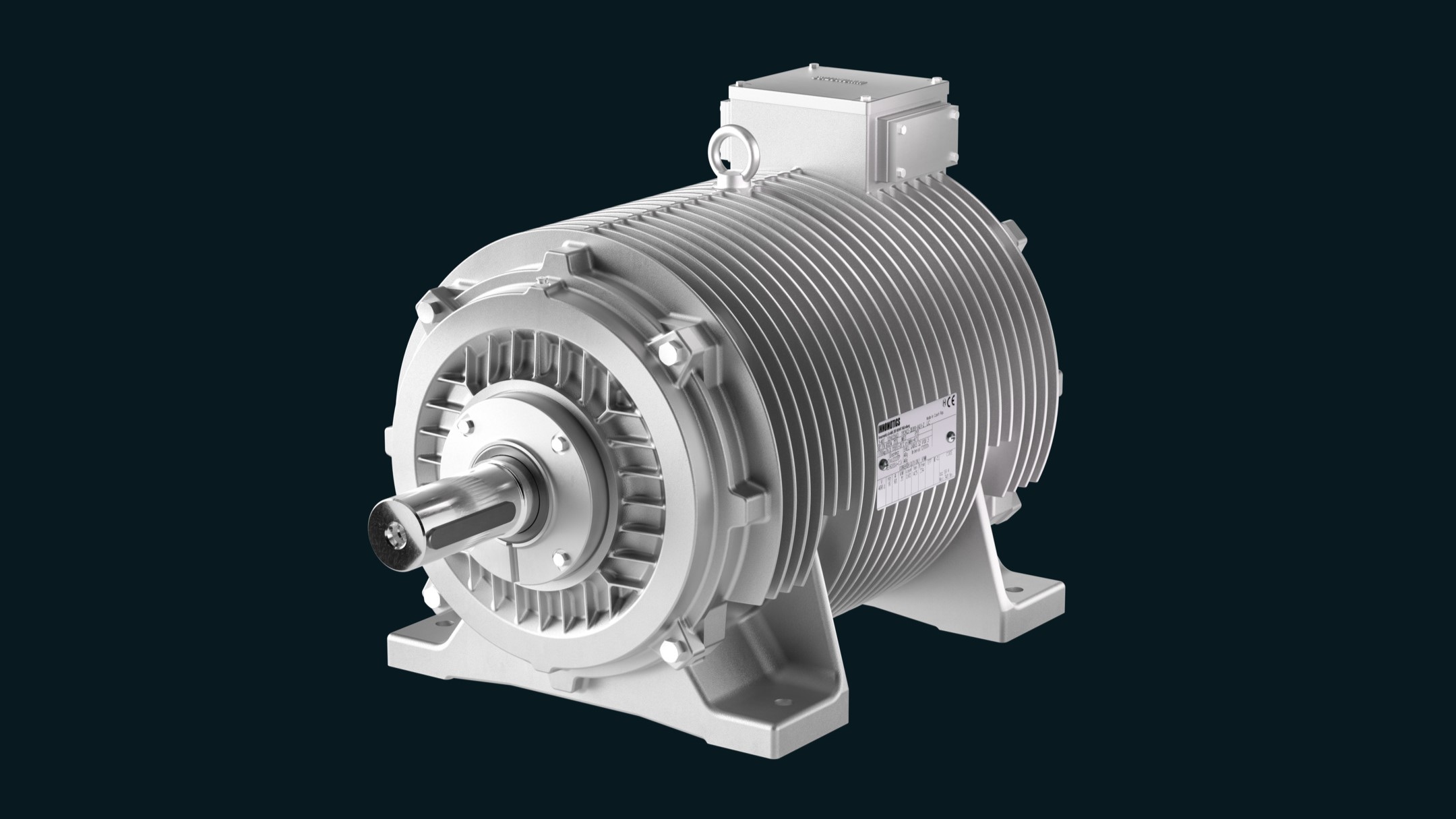

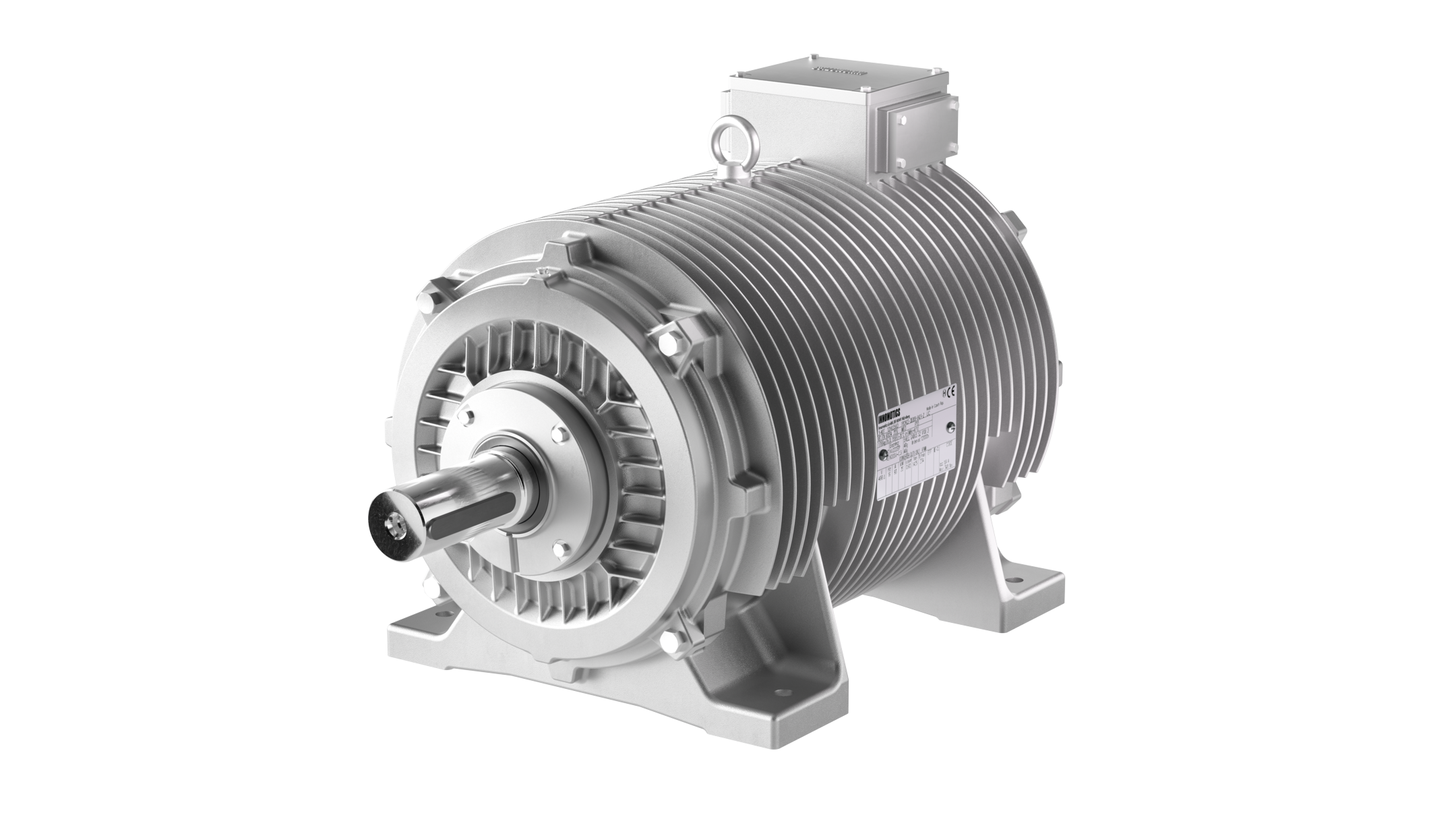

Salt-laden air and high humidities can place a lot of stress on electrical equipment installed in systems on ships and in coastal areas. This is the reason why renowned marine classification societies formulate strict regulations regarding supplementary qualifications as well for electric motors. Innomotics DP marine motors satisfy the specifications of leading marine classification societies (BV, DNV, GL, LR, RS, KR, ABS, RINA). For example, they are fully adapted to operate at higher ambient temperatures below deck. When required – or if the society`s regulations specify it - a representative of the marine classification society can be present in our factories to formally accept equipment. We also have motors specifically designed for on-deck operation. These have been designed so that they reliably function even when briefly flooded by waves.

An overview of the technology

Voltage and power range | 0.37 kW - 378 kW with all the usual voltages Up to 1250 kW with Innomotics TN or 1600 kW with Innomotics FD |

|---|---|

Frame sizes and types of construction | 63 M - 315L in all the usual types of construction Up to 450 with Innomotics TN or Innomotics FD |

Rated speeds and torques | 750 - 3600 rpm 0.61 - 10300 Nm |

Approvals for marine drives | Certificates for DNV GL, BV, LRS, RS, KR, ABS and RINA for below-deck applications |

Benefits

The type-tested Innomotics DP marine motors are available with aluminum or with cast iron enclosure – both in a standard version and versions for hazardous zones. They have been specifically designed and certified for below-deck applications, e.g. for auxiliary drives in fans, pumps and compressor drives – as well as for the offshore industry, e.g. on drilling rigs.

Typical applications

Our type-tested marine motors have been specifically designed for below-deck applications on ships and for the offshore industry, e.g. drilling rigs.

Examples of auxiliary drives on ships:

- Pumps, fans and compressors (e.g. for HVAC systems, water for firefighting and cooling, fuels, oils)

- Winches (anchor and mooring winches, lifting gear)

- Bow thruster drives

Maximum power - even when things get stormy

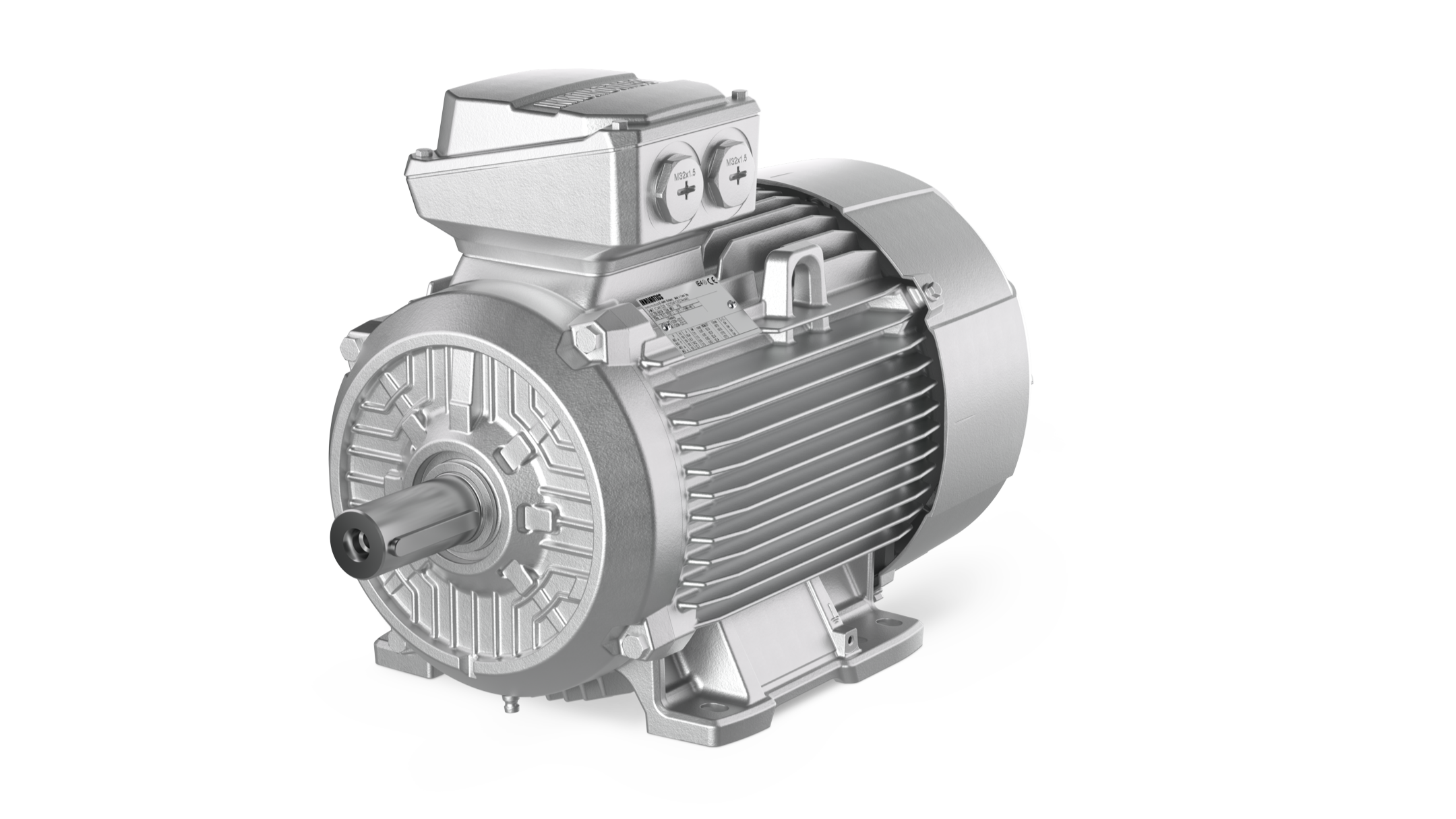

Innomotics DP crane motors are especially suitable for use in ports, where they are frequently subject to extreme weather conditions. They must be able to stand up to high humidity levels, salt-laden air and high wind speeds, while still guaranteeing a high overload capability and wide speed control range. Having said that, reliable functionality still has top-most priority.

An overview of the technology

Voltage and power range | 1.1 kW - 481 kW with all the usual voltages - as well as operation with Innomotics converters |

|---|---|

Frame sizes and types of construction | 132 S - 315 L in all the usual types of construction |

Rated speeds and torques | 727 - 1726 rpm 10.6 - 3142 Nm |

Benefits

- Higher efficiency

The use of active parts for high efficiencies also helps save energy when operated with a converter. For ambient temperatures up to 50°C, optionally also higher – protected against humidities up to 100% and salt-laden atmosphere. - More power

Torque reserves allow high surge loads – and an overload capability up to 230% – as accelerating drives, our crane motors can always admirably cope with any situation. Compact dimensions are achieved as a result of the high-power density. - More flexibility

With a generously dimensioned terminal box, corrosion protection inside the motor and optionally available rugged mounting feet and flanges manufactured out of torsionally stiff spheroidal cast iron, our crane motors are ready to take on any task.

Typical applications

The rugged cast iron motors have been specially developed for operation in harsh environments in adverse conditions typical for crane applications in salt-laden air with high humidity and winds. Typical uses for various crane applications in ports – such as gantry drives, trolley drives, boom drives as well as hoist drives.

Powerful drive, extremely rugged – the application defines the optimum product

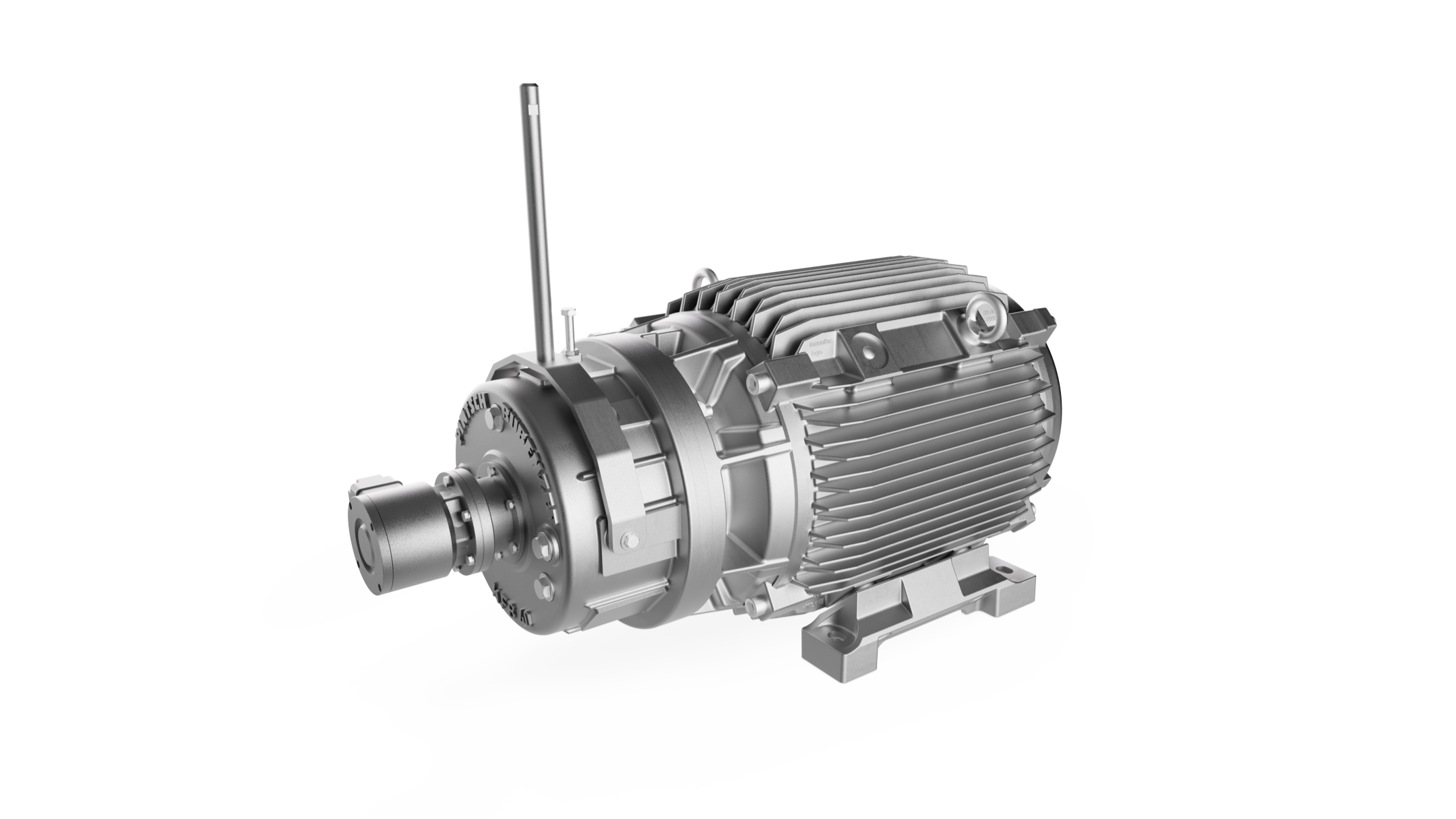

Today, transport and rolling operations with reversing operation in rolling mills are almost exclusively equipped with directly driven rolls. The mechanical and electrical requirements for a drive differ. To comply with these requirements, our new Innomotics DP roller table motors and new Innomotics DP steel plant motors have been developed for converter operation.

Rugged, non-ventilated Innomotics DP roller table motors are especially suitable to stand up to the very rugged operating conditions in rolling mills, in rolling and transport roller tables, at high ambient temperatures, high humidity levels and scale dust. The torsionally stiff enclosure manufactured out of spheroidal cast iron is especially rugged with respect to mechanical stress. Furthermore, the ring-ribbed enclosure avoids deposits of scale dust.

Innomotics DP steel plant motors are available with longitudinal-ribbed enclosures. These are suitable for areas that are less polluted and dirty – as well as for pure line operation. These motors have been designed to cope with medium vibration/shock and polluted areas in the area of transport roller tables.

Both are implemented as fully enclosed, three-phase induction motors. Torque reserves allow high surge torques of up to 400%.

Steel plant motors | Roller table motors | |

Voltage and power range | 1 - 38 kW with all the usual voltages | 3.5 kW - 66 kW with all the usual voltages |

Frame sizes and types of construction | 112M - 280M:IM B3, IM B5, IM V1, IM V3, IM B35 | 112M - 200L: IM B3, IM B5225M - 400: IM B3 |

Rated speeds and torques | 1000 - 2610 rpm 26 - 578 Nm | 295 - 1480 rpm 23 - 2135 Nm |

Degrees of protection | IP55, higher degrees of protection optionally available | FS 112M - 200L: IP66 FS 225M 400 IP55, higher degrees of protection optionally available |

Benefits

- Very rugged

The torsionally stiff enclosure manufactured out of spheroidal cast iron is especially rugged with respect to mechanical stress. Furthermore, the ring-ribbed enclosure avoids deposits of scale dust. The steel plant motors are also available with enclosures with longitudinal ribs for areas that are not so polluted and dirty. - More power

Torque reserves allow high surge torques of up to 400%. Converter-capable up to a line voltage of 460 V; optionally available with special insulation up to 690 V. - More flexibility

The motor winding is optimally designed for converter operation based on the data of the customer's application. Optionally available with mounted rugged rotary pulse encoder.

Typical applications

Rugged, non-ventilated roller table motors are especially suitable to stand up to the very rugged operating conditions encountered in rolling mills, in rolling and transport roller tables, at high ambient temperatures, high humidity levels and scale dust.

Steel plant motors can also be used in transport roller table areas that are less dirty and polluted.

Special solutions for special drive applications - also in large unit quantities

Whether customers require special mechanical attributes, adapted electrical operating values or system solutions – for many years now, Innomotics has been a reliable partner in creating customized solutions. We have already realized high-speed drives for the textile industry and compressor applications, motors with an increased power density, liquid-cooled motors, motors for woodworking systems, system drives for industrial applications and synchronous generators for standby power supplies – the possibilities are simply endless. Simply contact us without any obligation. We can certainly find the optimum solution for you. This is because Innomotics is also a strong partner for those applications where standard motors have to satisfy additional, specific customer requirements.

Benefits

Sample of customized solutions that we have already implemented:

- High-speed drives for the textile industry and compressors

- Motors with increased power density

- Liquid-cooled motors

- Synchronous generators for standby power supply systems

- Motors for woodworking systems

- Integrated motors for refrigerating compressors (immune to refrigerants)

- Roller table motors for harsh environmental conditions, e.g. rolling mill drives

- Pump motors with special shafts/special material

- Single-phase motors for industrial applications

- Motors for pumps with integrated pump flange

Typical applications

- Suitable use under special application conditions

More information about Innomotics DP Definite Purpose Motors

- Services