Driving fluid flow engines towards the ultimate productivity

Improve energy efficiency with synchronous-reluctance drive systems

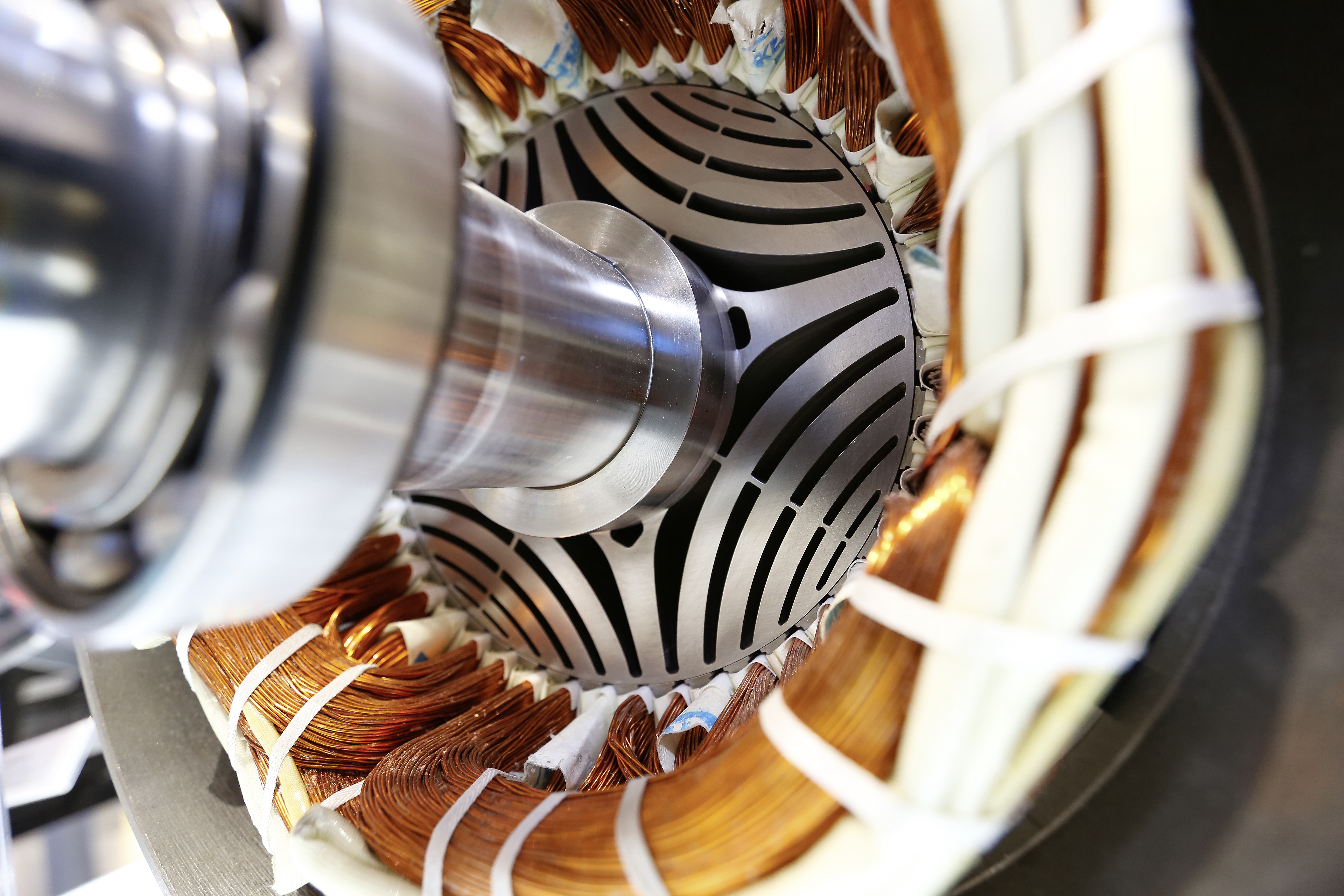

Focusing on efficiency

Synchronous-reluctance drive systems features high control dynamics and high speed stability in encoderless operation and allow high productivity with minimum operating costs thanks to extremely low power consumption.

The way to fast, efficient operation. A perfectly harmonized solution

Digitalization is becoming more and more prominent in all industries. Thus, the new generation of synchronous-reluctance systems offers powerful advantages to obtaining the necessary information from motors. Thanks to the knowledge gained, production can be strengthened and driven forward in a targeted manner. The Digital Twin and the SIMOTICS Digital Data App are the key to the digitized world of synchronous-reluctance drive systems.

Focusing on technical benefits

Drives with synchronous-reluctance technology are characterized by very high levels of efficiency, particularly at part load. As an integrated drive system, the reluctance motor and inverter are carefully coordinated and enable a particularly economical operation. Significant efficiency benefits can be seen as a result of the seamless integration into automation as well as through efficient engineering and service concepts across the entire lifecycle.

Focusing on economics

Approximately 97% of the life cycle costs are motor-based energy costs. The high efficiency of synchronous-reluctance drive system ensures minimal operating costs and energy optimization, a short payback period, and a fast return on investment.

Drive technology that pays off fast

The benefits of the synchronous-reluctance drive system include investment security, reduced operating costs, and rapid amortization. When compared to standard induction motors in IE2, the higher initial investment paid off in less than 12 months, when compared to a drive system with an IE3 motor it even paid for itself after five months with a pump load cycle in accordance with the standardized profile "Blue Angel" in two-shift operation and energy costs of 8 ct/kWh.

More information on synchronous-reluctance drive systems

Find downloads, support and services for synchronous-reluctance drive systems.

- Services

Service Links

Practical use of synchronous-reluctance drive systems

Have a look at some application examples that may be of interest to you.

- Increased energy efficiency in upright presses

- System solution with Innomotics converter-oriented synchronous-reluctance motor (VSD 4000) and modular SINAMICS G120 frequency converter

- High efficiency thanks to the highest system efficiency class IES2

- Simplified press hydraulics through control via a SIMATIC S7-1500 PLC with fail-safe CPU

- Show more

- Integrated Drive Systems with Innomotics GP reluctance motor and SINAMICS G120 converter

- Outstanding energy efficiency - System efficiency is increased by 10% in the partial load range

- Perfect controllability as a result of the harmonized and coordinated drive system

- Integrated Drive Systems with Innomotics reluctance motors

- Minimum operational costs and high productivity

- Ideal realization of customer requirements – adjustment of machines to the product

- Integrated Drive System with Innomotics synchronous-reluctance motor and SINAMICS G120 converter

- Excellent energy efficiency, especially with partial load

- Simplified commissioning with motor code