Oil-lubricated rolling bearings

Less maintenance. More uptime.

Prevent rolling bearing failures right from the start

Our patented oil-lubricated rolling bearings ensure continuous lubrication of your bearings and avoid downtime due to motor damage or maintenance. For more availability and long-term cost savings.

Oil-lubricated rolling bearings: the smart choice for reliability

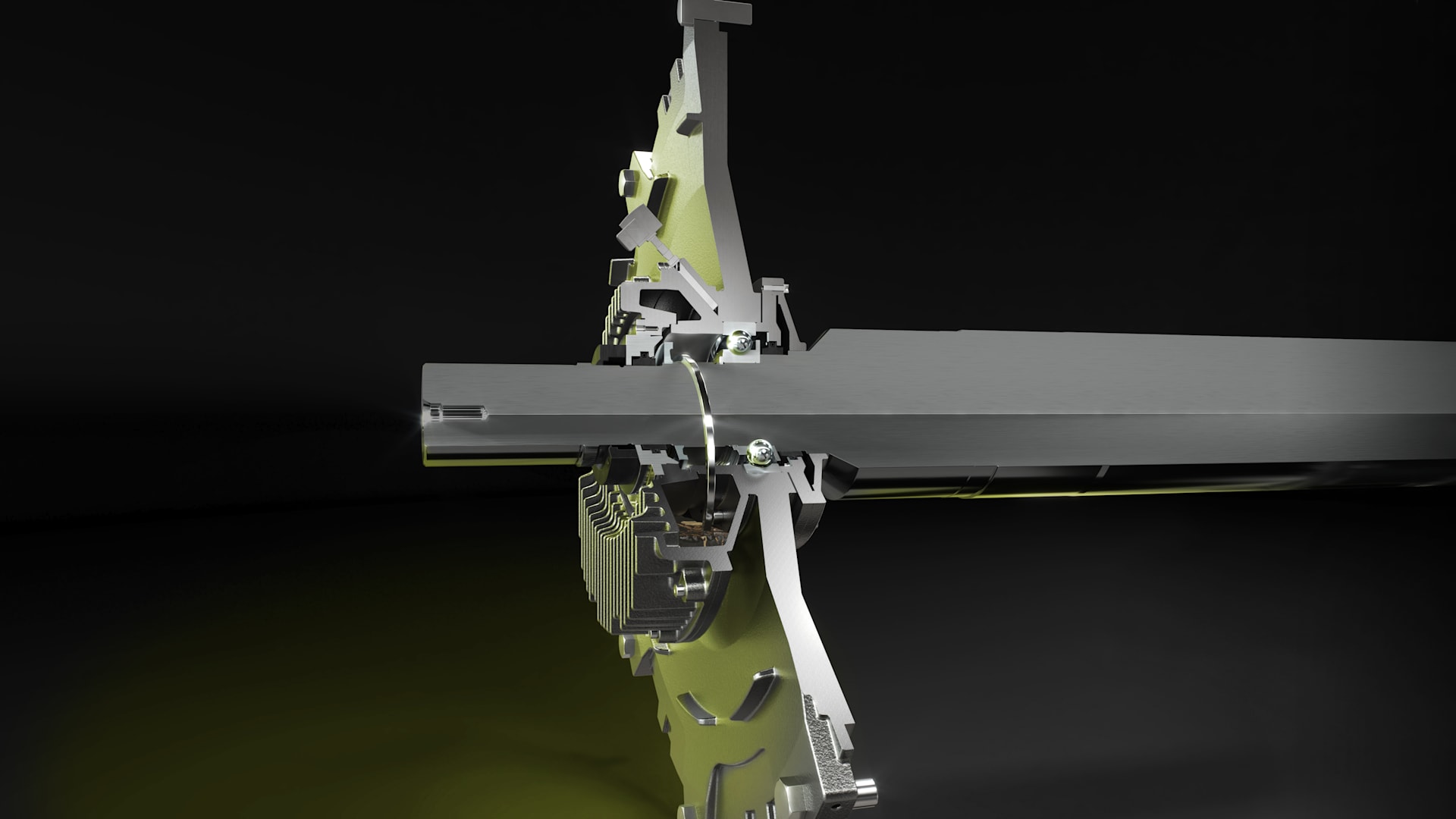

How oil-lubricated rolling bearings work

The oil lubrication system includes an oil ring similar to a sleeve bearing housing, which circulates the oil and distributes it across the anti-friction bearings. As the motor shaft turns, the oil ring also rotates, picking up oil from the oil reservoir. This oil ring carries the oil upward, and gravity helps spread it over the shaft and bearings for lubrication. The bearing housing uses oil seals and gap seals to create a sealed chamber suitable for harsh, dirty, dusty outdoor environments, both hazardous and nonhazardous, with ingress protection rated up to IP56. You benefit from high reliability, less maintenance, and less potential sources of error. Watch the video to discover our technical solution in detail.

Essential Facts at a Glance

Dive deeper into Oil‑Lubricated Roller Bearings (OLRB). Our technical brochure lays out the key design principles, maintenance advantages, and safety benefits in a clear, compact format - tailored to your industry needs.

Your competitive edge with oil-lubricated bearings

Curious to know more?

Explore the full benefits of oil-lubricated rolling bearings in our whitepaper or get in touch with our team for tailored advice.

FAQs

Would you like to learn even more about oil-lubricated rolling bearings? Let’s go more into more detail. Below, we answer the most important questions for you.