Digital simplicity for complex industrial processes

Our promise to deliver reliable motors and drives is at the core of everything we do at Innomotics. With our commitment to innovation, we are working on a digital ecosystem that reduces complexity, delivers value to customers, and seamlessly integrates distributors. In a conversation with Patrick Christleven, Head of Promotion, Tools & Marketing (Digital CX & AI) for the Low Voltage division, we explore our current digital offerings and the promising path ahead.

Digital solutions are the key to success in today’s industrial and commercial landscape and that’s where our digital ecosystem comes in. What do customers expect from digital tools, and how are we responding?

Patrick Christleven: It’s about digital simplicity. Customers expect in their professional or personal environments intuitive, streamlined solutions, not complexity. This benefits both end customers and distributors who need real-time information – for example datasheets, CAD models, quotation documents, or the status of their order.

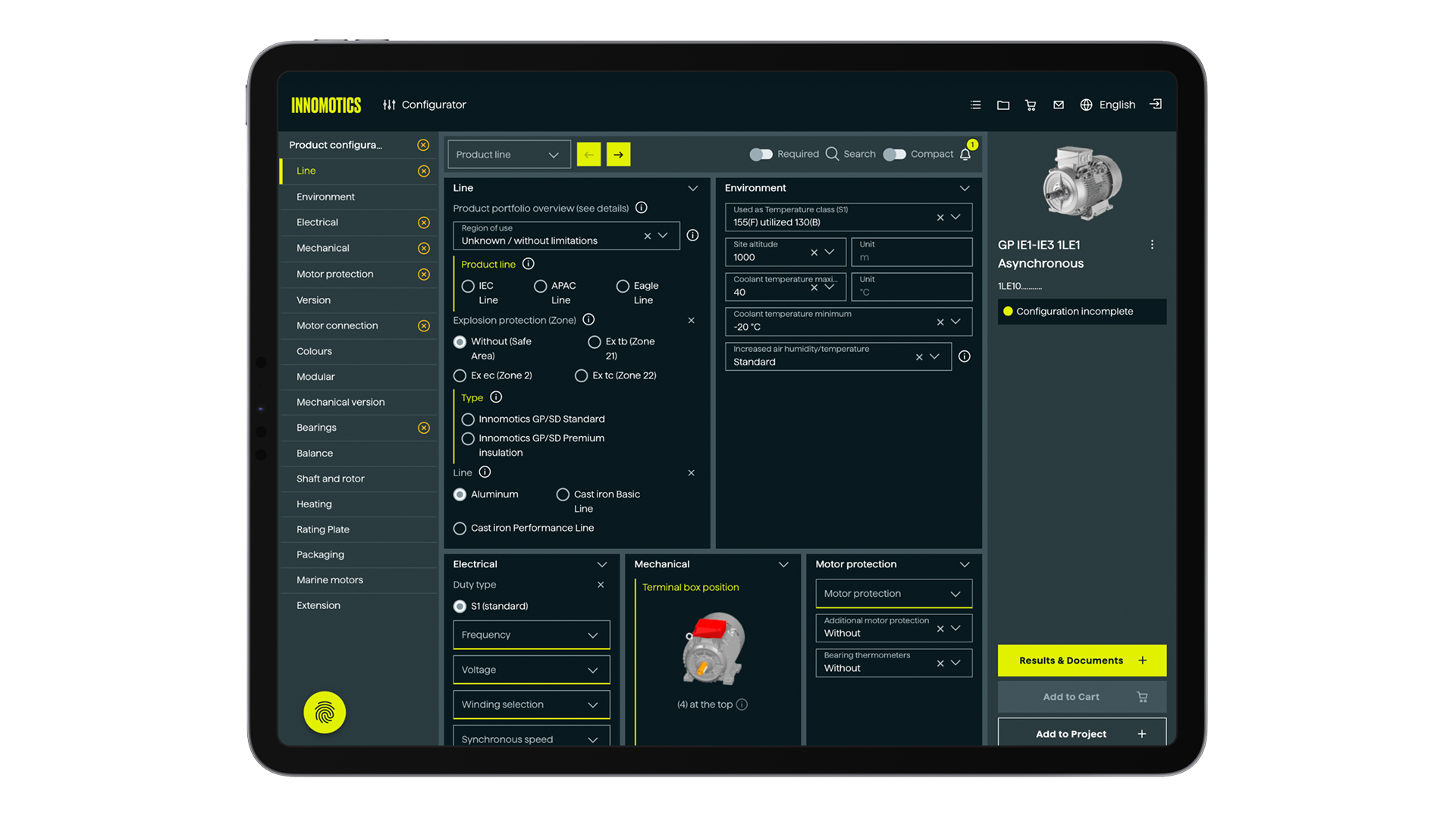

A single tool is no longer enough, we are building a digital operating system for the customer journey. With the Configurator, we have already laid a strong foundation. Within minutes, it delivers precise solutions with all relevant documents that can be transferred directly to the shop. We are now developing this into a fully integrated, end-to-end platform.

Start with the Innomotics Configurator

The configurator is a digital product catalog where our motors can be configured. From model series to protection zones or electrical parameters like frequency, voltage, winding, and speed, it guides you through our entire portfolio. Afterwards, technical documents, CAD data, or other files can be downloaded, and the product can be ordered directly.

Currently, our Low Voltage and Geared Motors are available for configuration. More products will follow soon.

What are the next expansion stages, and how will our tools continue to evolve?

Patrick Christleven: The next big step is the seamless integration of the shop and Configurator. Customers will start with inspiration, selecting their use case, such as conveyor belt, ventilation, or pump, and the platform will automatically recommend the most suitable solution. This approach supports users who may not have all the technical details at hand.

Direct product configuration and MLFB (Machine-readable Product Designation) input will remain as core features. At the same time, our distributors are fully integrated: real-time conditions, digital ordering processes, seamless interaction. This creates a platform ecosystem that elevates speed, clarity, and collaboration to a new level.

The future is use case-driven journeys where we automatically suggest the right solution to customers, even if they do not know all the technical details.

Patrick Christleven, Head of Promotion, Tools & Marketing (Digital CX & AI)

Does AI play a role in this transformation? This Technology currently dominates development in many areas. What can it do in configuring motors, drives or full drive systems?

Patrick Christleven: Artificial intelligence is a driving force behind our next evolution. With GenAI and AI Agents, we are taking the next big steps:

- Dynamic configuration optimization

- Sustainability and efficiency embedded in every decision,

- Virtual assistants guiding customers and distributors as digital co-pilots.

Seamless Integration is crucial. CRM and CPQ processes are directly connected, enabling fully automated workflows from configuration to quotation. For back- office teams, this means fewer routine tasks, reduced errors, and more focus on value creation. Our platform thus evolves from a tool into an intelligent, adaptive ecosystem that learns and evolves with every interaction.

How advanced is this integration? What do users today?

Patrick Christleven: We are already implementing integrated processes. Especially for standard products, many tasks now run automatically. For more complex MTO+E (Make-to-Order + Engineering) products, we are actively developing solutions. From initial configuration to final quotation, the process is seamless, automated, and faster.

However, technology alone is not enough. My team combines partner management, training, digital tools, and marketing. This interdisciplinary approach is our strength. True transformation happens when people and technology work together. Our goal is clear: to position Innomotics Low Voltage as a digital pioneer with AI-powered platforms, a strong partner ecosystem, and an excellent customer journey. For us, transformation means aligning technology, processes, and people to create real value.

Read more in our Insights Magazine

Discover more insights and innovations in our related articles section. Explore additional stories that complement your reading and keep you moving forward with Innomotics.